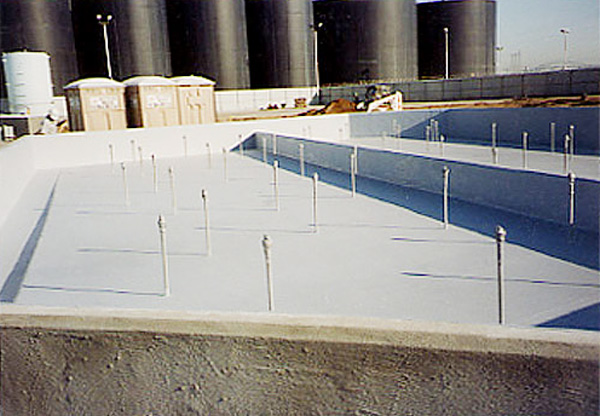

We protect your concrete or steel containments from corrosion with coating inspection, failure analysis, surface preparation, lining application, and site maintenance programs. These programs are specially designed for highly corrosive environments and curbed containments around storage areas. Offering installation services for a range of elastomeric epoxy coatings, flexibilized containment linings, as well as fiberglass reinforced coatings and linings, is our specialty.

With the help of our chemical resistant containment linings and protective coatings, industrial manufacturers can protect their collection sumps, trench systems, as well as tanks from product or process liquid spills. To identify containment requirements, our team of experts will visit your site and provide a detailed proposal. Based on your custom containment needs, the team will help you select protective coatings or high performance epoxy coatings with chemical plus physical resistant properties.

By using high performance containment linings as well as coatings, we repair worn, uneven joints, cracks, and other major defects in the containments. As a result of our renovation, efficient foot and vehicular traffic is restored at your facility. Through our surfacing and coating programs, you can reduce product spills and damage, which in turn will help you save material handling as well as repair costs.

CAPABILITIES

- Coating Equipment

Brushes

Rollers

Sprayers

- Services

Cleaning

Finishing

Floor Re-coating

Inspection

Installation

Material Selection

Renovation

Repair and Restoration

Testing

Waterproofing and Resurfacing

- Surface Preparation

Acid Etching

Diamond Grinding

Scarification

Shot Blasting

SPECIFICATIONS

- Types of Containment Linings

Chemical Storage Area Linings

Fiberglass Reinforced Linings

Flexibilized Containment Linings and Flooring Systems

Hazardous Waste Storage Linings

Secondary Containment Linings

Tank Linings

Trench and Sump Linings

- Types of Containment Coatings

Elastomeric Epoxy Coatings

Fiberglass Reinforced Coatings

Secondary Containment Coatings

- Tensile Strength

400 – 800 psi

- Standards Met

EPA

NPDES

SSPC

Additional Information

- Containment Lining & Coating Features

Chemical Resistant

Cleanability

Corrosion Resistant

Easy to Maintain

Impact Resistant

Liquid-Tight Integrity

Moisture Resistant

UV-resistant

Weather-Proof

- Applications

Berms

Collection Sumps and Pits

Concrete Tanks

Containment Curbs

Fiberglass Tanks

Retaining Walls

Trench Systems

- Industries Served

Food and Beverage

Aerospace

Automotive

Commercial Spaces

Manufacturing

Chemical

Petrochemical Processing

Packaging

Electronics/ Telecommunications

And Many Mores

- Client List

Alcoa Fastening Systems

And Many More

BF Goodrich

Boeing

CBS Television Network

General Motors/ Delphi Battery

Honeywell

McDonnell Douglas

Nabisco

Nakano Foods

Walt Disney Imagineering